UrbanStone Concrete Pavers from Jandakot, Western Australia

Brickworks Upfront Carbon Emissions

kg CO2e / tonne (A1-A3)

kg CO2e / tonne (A1-A3)

193.11

above NABERS average

GWP - Fossil

193.00 kgCO2e

GWP - Biogenic

0.10 kgCO2e

GWP - LULUC

< 0.01 kgCO2e

GWP - Stored

0.00 kgCO2e

This data has been generated from publicly available EPD data.

Upfront Carbon Emissions is a summation of Fossil, Biogenic and Land Use emissions. It does not include biogenic sequestration. This is consistent with NABERS database.

Valid until: 18 June 2030

Upfront Carbon Emissions is a summation of Fossil, Biogenic and Land Use emissions. It does not include biogenic sequestration. This is consistent with NABERS database.

Valid until: 18 June 2030

Do you have any questions on this data?

Please contact us

Please contact us

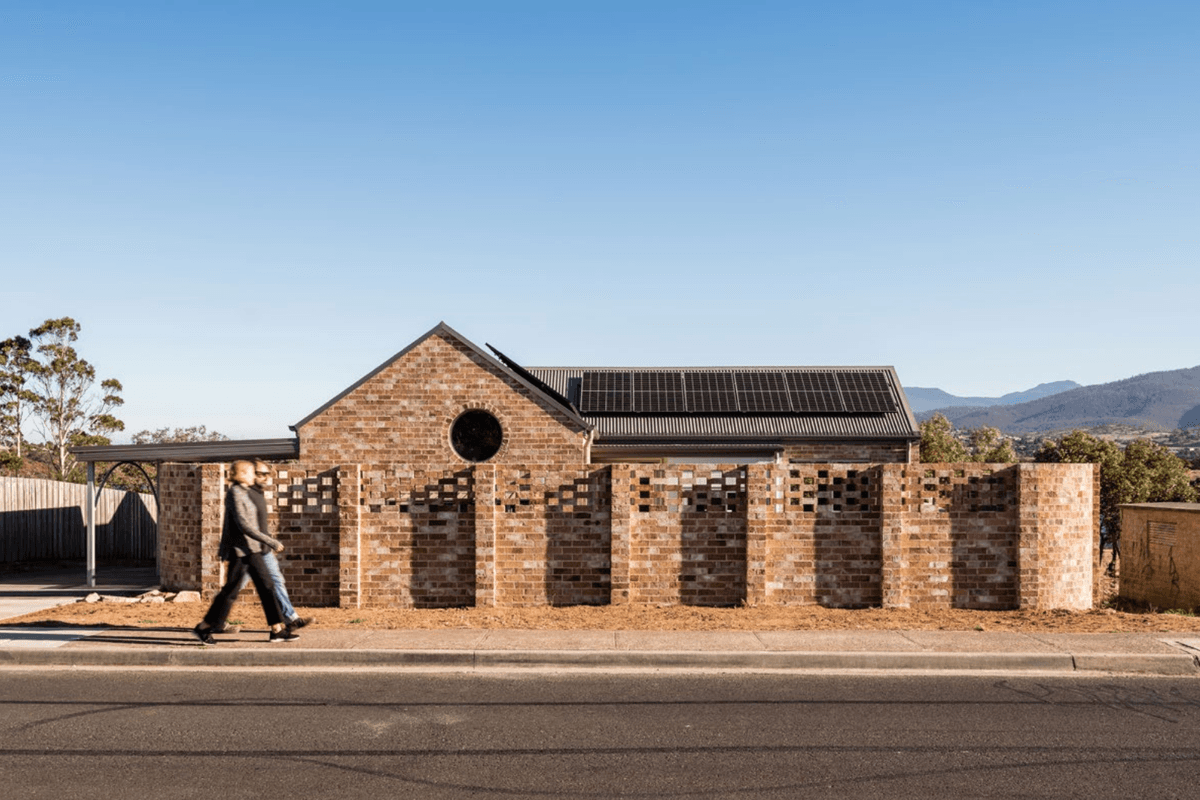

The life cycle of wet cast pavers starts with extraction of sand, gravel and cement from quarries and mines. The processed materials are then mixed with oxide and poured into moulds where the mix is vibrated to release air bubbles in the mix and allowed to cure into the mould which creates the desired paver size and finish.

The process of pouring wet concrete into moulds where they are allowed to cure is called 'wet casting'. Wet cast pavers are used in residential and commercial landscape applications. This EPD covers the wet cast pavers produced at our Jandakot Western Australia plant under the UrbanStone brand.

UrbanStone produces a significant number of product variations based on a limited number of concrete mix designs. To present ...

Pricing

Availability

In Stock

Downloads

Environmental Product Declaration

PDF • 1.4MB

About Brickworks

Brickworks is one of Australia’s largest and most diverse building material manufacturers. Austral Bricks is the subsidiary of Brickworks that manufactures and sells Australian made and imported clay bricks and pavers. Brickworks has manufacturing operations in New South Wales, Victoria, Tasmania, South Australia, Queensland and North America. The company produces clay brick products mainly used in residential and commercial construction, offering a wide range of colours, textures, and styles.

Phone

(02) 9830 7800

Similar Products

Thin Tech Plus System (average product)

44.50

Upfront Carbon Emissions

kg CO2e / unit (A1-A3)

kg CO2e / unit (A1-A3)

N/A

NABERS average

Tru-Brix System (average product group)

56.30

Upfront Carbon Emissions

kg CO2e / unit (A1-A3)

kg CO2e / unit (A1-A3)

N/A

NABERS average

Concrete Masonry from Austral Masonry (Ayr, Queensland)

Upfront Carbon Emissions

kg CO2e / unit (A1-A3)

kg CO2e / unit (A1-A3)

below NABERS average

Clay bricks and Pavers from Austral Bricks and Daniel Robertson (Longford, Tasmania)

Upfront Carbon Emissions

kg CO2e / unit (A1-A3)

kg CO2e / unit (A1-A3)

below NABERS average

Dark Concrete Retaining Wall from Austral Masonry (Rockhampton, Queensland)

Upfront Carbon Emissions

kg CO2e / unit (A1-A3)

kg CO2e / unit (A1-A3)

below NABERS average

Grey Blocks from Austral Masonry (Cairns, Queensland)

Upfront Carbon Emissions

kg CO2e / unit (A1-A3)

kg CO2e / unit (A1-A3)

below NABERS average

Grey Masonry Blocks and FBR Blocks from Austral Masonry (Jandakot, Western Australia)

Upfront Carbon Emissions

kg CO2e / unit (A1-A3)

kg CO2e / unit (A1-A3)

below NABERS average

Coloured Masonry Blocks and Masonry Retaining Walls from Austral Masonry (Jandakot, Western Australia)

Upfront Carbon Emissions

kg CO2e / unit (A1-A3)

kg CO2e / unit (A1-A3)

below NABERS average