GGBFS - Slag

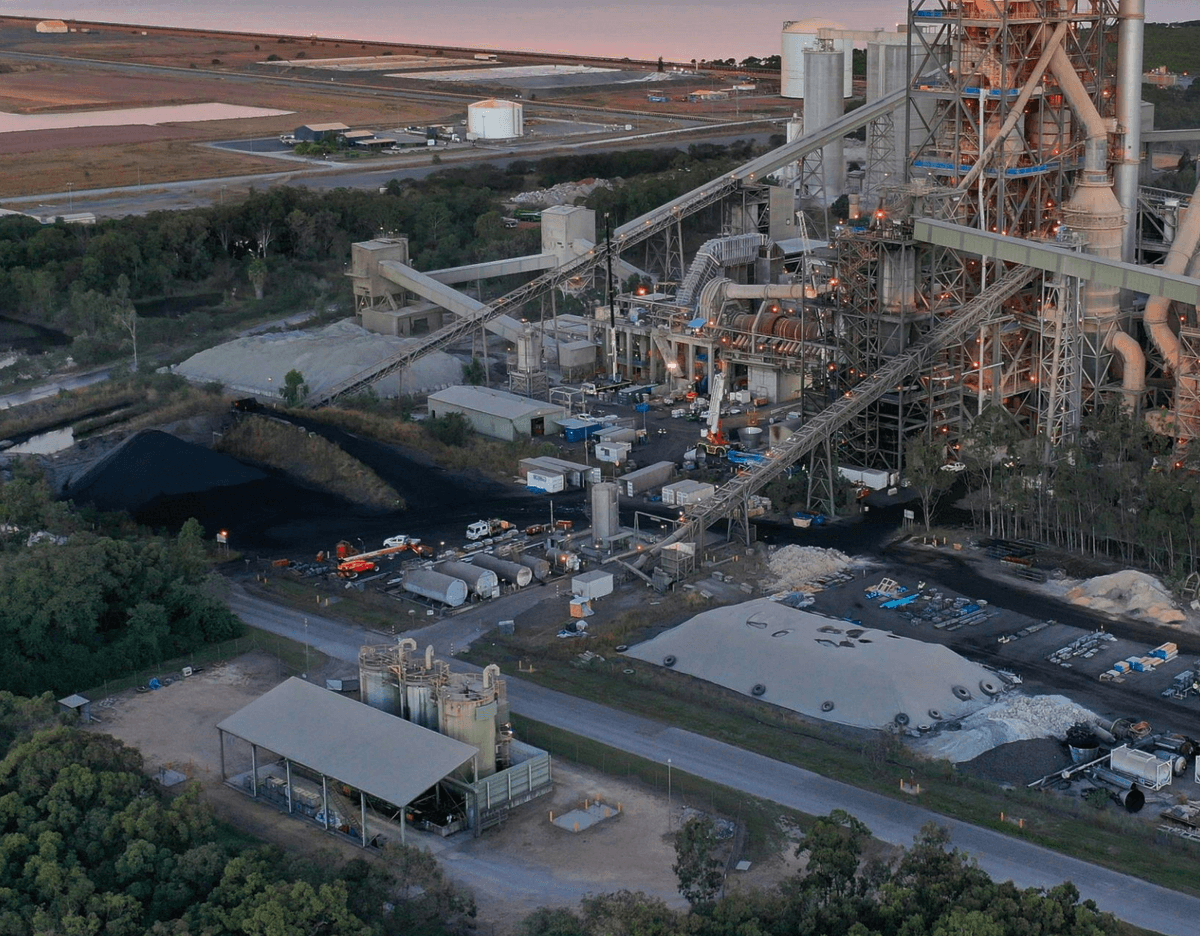

Cement Australia Pty Ltd

Total Upfront Carbon (Fossil)

kg CO2e / tonne (A1-A3)

kg CO2e / tonne (A1-A3)

169.74

GWP - Fossil

169.74 kgCO2e

This data has been calculated using Rebuilt's Product Carbon Footprint assessment tool.

Do you have any questions on this data?

Please contact us

Please contact us

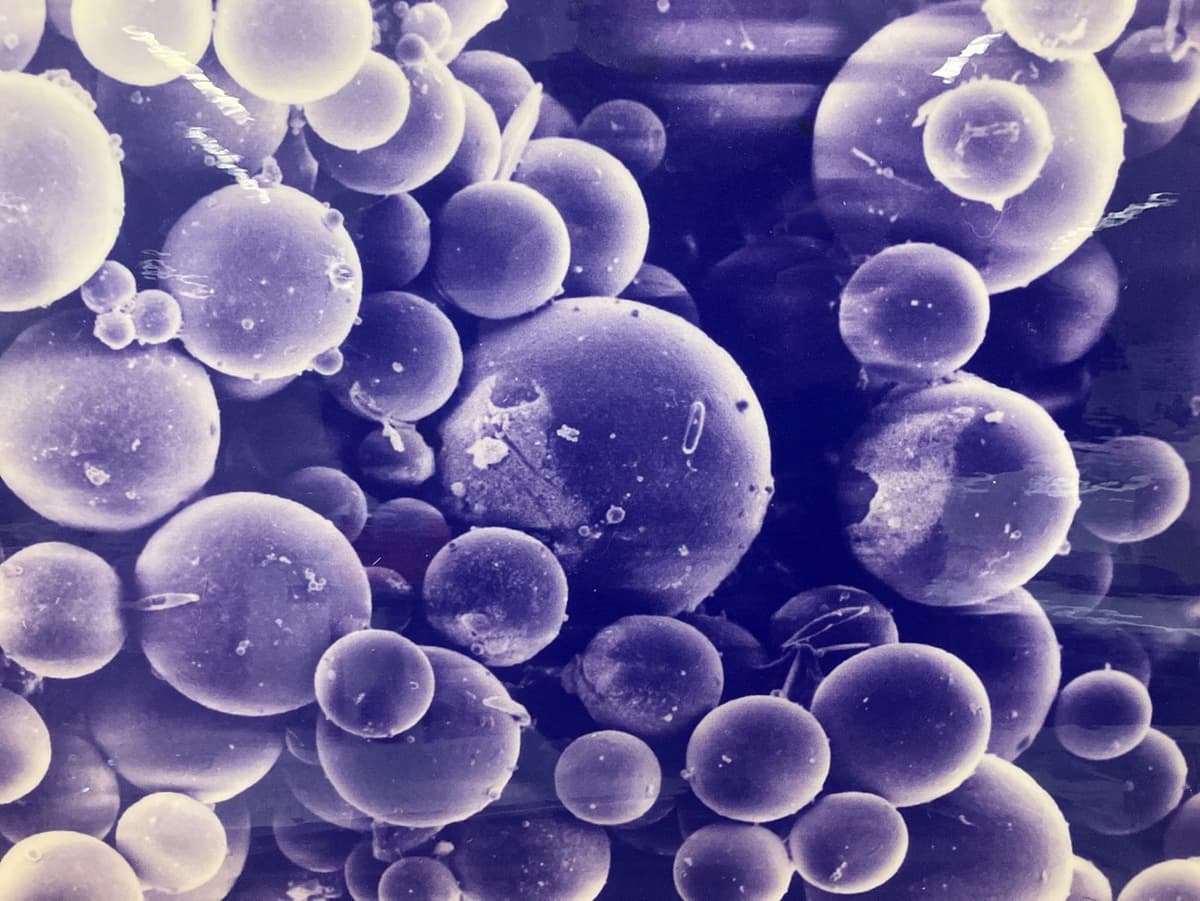

Ground-granulated blast-furnace slag (GGBFS) is produced by quenching molten iron slag (a by-product of iron and steel-making) from a blast furnace in water, to produce a granular product that is then dried and ground into a fine powder. GGBFS enhances a range of performance characteristics such as the reduction of the heat of hydration in mass concrete pours, reduction of concrete permeability and improvement of durability properties in resistance to aggressive environments. Similar to fly ash blends, early age strength development of slag blends is slower than straight cement concrete however strength development from 28 days onwards is equivalent or better. Cement Australia GGBFS complies with the requirements of Australian Standard AS...

Product specifications

Net weight

1,000.00 kg

Pricing

Availability

In Stock

Downloads

Rebuilt PCF - GGBFS - Slag

PDF • 2.5MB

About Cement Australia Pty Ltd

Cement Australia’s main business involves the manufacture and sale of cement and cementitious products in Australia. Cement Australia manufactures high performance cement products, including customised blends for special applications.

In addition, we supply concrete-grade fly ash and ground granulated blast furnace slag, along with high grade lime products in bulk and packaged forms. Our products meet required Australian Standards and have been tested to withstand Australian climate conditions. Cement Australia operates in accordance with its management systems, which are certified to the following International Standards:

• ISO 9001 Quality Management Systems

• ISO 14001 Environmental Management Systems

• ISO 45001 Occupational Health and Safety Management Systems.

Phone

1300 236 368

Similar Products

Gladstone Fly Ash Blend

527.00

Upfront Carbon Emissions

kg CO2e / unit (A1-A3)

kg CO2e / unit (A1-A3)

N/A

NABERS average

Low Carbon Cement

544.00

Upfront Carbon Emissions

kg CO2e / unit (A1-A3)

kg CO2e / unit (A1-A3)

N/A

NABERS average

Goliath General Purpose Cement

757.00

Upfront Carbon Emissions

kg CO2e / unit (A1-A3)

kg CO2e / unit (A1-A3)

N/A

NABERS average

Gladstone General Purpose Cement

827.00

Upfront Carbon Emissions

kg CO2e / unit (A1-A3)

kg CO2e / unit (A1-A3)

N/A

NABERS average

Port Kembla General Purpose Cement

846.00

Upfront Carbon Emissions

kg CO2e / unit (A1-A3)

kg CO2e / unit (A1-A3)

N/A

NABERS average

Bulwer Island General Purpose Cement

861.00

Upfront Carbon Emissions

kg CO2e / unit (A1-A3)

kg CO2e / unit (A1-A3)

N/A

NABERS average

Fly Ash Grade 1

45.18

Upfront Carbon Emissions

kg CO2e / unit (A1-A3)

kg CO2e / unit (A1-A3)

N/A

NABERS average